Compression moulding

PREPARATION

The raw materials (“Masterbatch” elastomer base) received are mixed with additives (plasticiser, carbon black, mineral filler...) between two mixing rollers giving it processing and hardness properties. The material has to go through many times in order to achieve homogeneity in semi-finished slab form.

Once the elastomer slab is calibrated for thickness, it is cut into multiple strips. There is 100% weight control for each strip to ensure the correct amount of material required.

VULCANISATION

The strips are positioned, using a specific tool, in the open compression mould. Once closed, the vulcanisation process begins. Vulcanisation (also called crosslinking) is a chemical operation that binds and forms a crosslinked chain of monomer bases.

The vulcanised mass in the mould is in the form of a horizontal layer (or cluster) integrating the parts as well as the membrane connecting them.

|

|

|

|

|

| Raw material |

Mixture of raw material |

Mixing and preparation roll material |

Cut into strips |

|

|

|

|

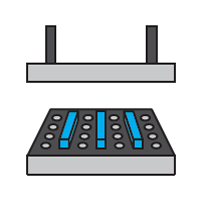

| Weighing | Placement of bands on the mold |

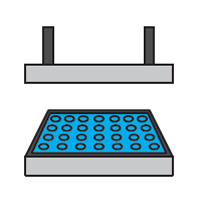

Cooking - Vulcanization | Obtaining the tablecloth parts + flash |