Simulation numérique

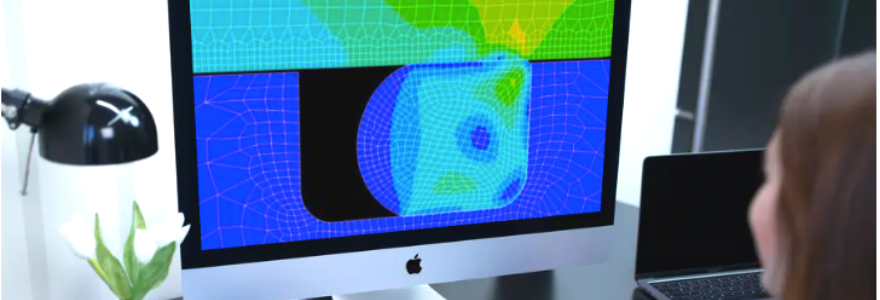

In order to speed up and improve the development of new sealing designs, France Joint uses the method of numerical simulation by finite elements, mainly non-linear.

To make the simulation as accurate as possible, good material characterisation is essential.

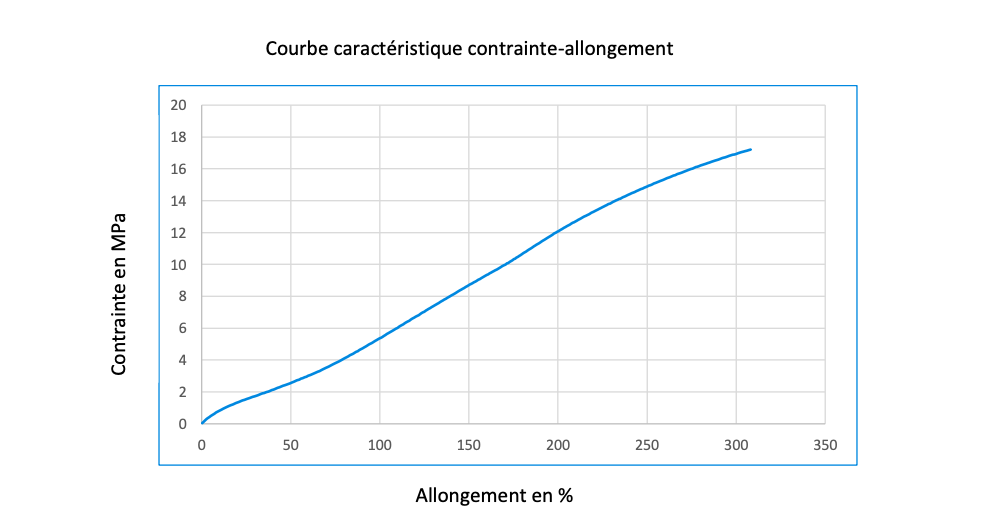

Generally, metal parts have a linear relationship between stress and strain up to a certain value, which makes the analysis relatively simple. However, in the case of elastomers, there is stress/strain non linear relationship of the material, and the deformation of the material can very often exceed 100%.

Tensile and compression tests on specific specimens are therefore carried out in our in-house laboratory to determine the material's relationship between its elongation and its stress/strain, in order to determine hyperelastic models for elastomers (Mooney-Rivlin, Ogden, etc.).

Below is an example of a stress/pressure-elongation characteristic curve :

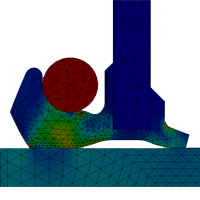

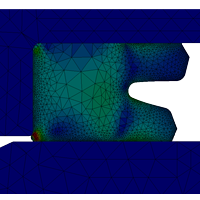

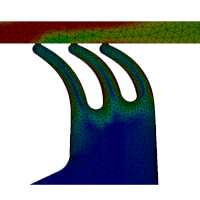

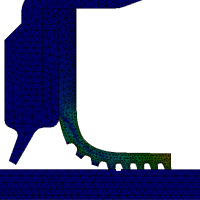

France Joint simulates its designs using tools such as ABAQUS and SOLIDWORKS SIMULATION, some examples of which are given below:

|

|

|

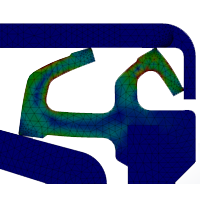

| Cassette seal | Zoom in on a cassette seal | High pressure shaft seal |

|

|

|

| Lip seal - Hydraulic - Rod | Triple lip shaft seal | Shaft seal – PTFE lip |