Injection moulding

PREPARATION

The plastic material (thermoplastic polymer) is received in the form of granules. For some applications, additives such as colourants can be mixed with the base material. The plastic material is dried with a drying process to remove the moisture present.

INJECTION

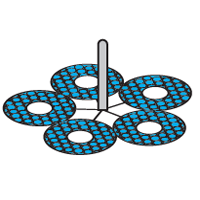

The plastic material is transferred and then softened in the revolving cylinder using a heated worm. Injected under high pressure, the material fills the mould cavities via the feeders at a temperature below the transformation temperature. In order to limit materials shrinkage during its cooling, a constant pressure is maintained. Once the cooling circuits have allowed the part to cooled, it is ejected from the mould.

|

|

|

|

|

|

| Raw materials | Addition of dye | Drying of the mixture |

Compression / heating of the material in the endless screw Injection and curing in the mold |

Obtaining the cluster |