BECA 010 PU

Description

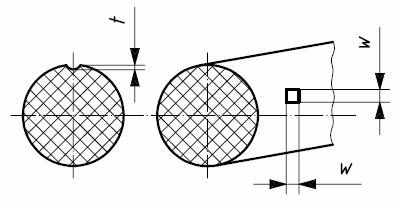

The BECA 010 PU is an O'Ring, a circular ring with a round cross-section, made from polyurethane.

Advantages

Excellent abrasion and wear resistance

Excellent extrusion resistance, accepting even the most significant extrusion gaps

Very good mechanical properties

Low friction

Technical data

| Temperature | -30°C / +110°C |

|---|---|

| Pressure | Up to 60 MPa in static applications |

| Speed | In linear applications only, up to 0.2 m/s |

| Medias | Mineral hydraulic oils |

Applications

Heavy-duty environments

Mining machinery

Materials

PU 70 Shore A - moulded

PU 93 Shore A - injected

PU 95 Shore A - machined

PU 96 Shore A - injected

Other materials may be used

Dimensions

Materials

PU (Polyurethane)

The polyurethane (PU) family has excellent mechanical features, such as wear resistance and tensile strength, and has a high elasticity compared to other rubbers.

| Chemical resistance | Aliphatic hydrocarbons (propane, butane) Mineral oils and greases Silicone oils and greases Water (up to +50°C max) |

|---|---|

| Compatibility issue | Ketones, esters, ethers, alcohols, glycols Hot water and steam Alkalis, amines, acids |

| Temperature range | -30°C / +90°C -30°C / +110°C with special PUs |

Design recommendations

The tolerances on the inside diameters Ød1 set out in the table below relate to standard ISO 3601-1:2008. If the dimensions of an O'Ring are not specified in standard ISO 3601-1:2008, we recommend that you calculate the tolerances to apply to the inside diameter Ød1 as follows:

Tolerance on Ød1 = ± [(d10′95 x 0,009) + 0,11]

| Inside diameter Ød1 |

Tol. | Inside diameter Ød1 |

Tol. | |

|---|---|---|---|---|

| 0,74 ≤ Ød1 ≤ 1,78 | ± 0,12 | 242,00 < Ød1 ≤ 244,00 | ± 1,77 | |

| 1,78 < Ød1 ≤ 3,00 | ± 0,13 | 244,00 < Ød1 ≤ 246,00 | ± 1,78 | |

| 3,00 < Ød1 ≤ 4,20 | ± 0,14 | 246,00 < Ød1 ≤ 247,00 | ± 1,79 | |

| 4,20 < Ød1 ≤ 5,50 | ± 0,15 | 247,00 < Ød1 ≤ 249,00 | ± 1,80 | |

| 5,50 < Ød1 ≤ 6,75 | ± 0,16 | 249,00 < Ød1 ≤ 250,00 | ± 1,81 | |

| 6,75 < Ød1 ≤ 8,10 | ± 0,17 | 250,00 < Ød1 ≤ 252,00 | ± 1,82 | |

| 8,10 < Ød1 ≤ 9,50 | ± 0,18 | 252,00 < Ød1 ≤ 253,00 | ± 1,83 | |

| 9,50 < Ød1 ≤ 10,69 | ± 0,19 | 253,00 < Ød1 ≤ 254,50 | ± 1,84 | |

| 10,69 < Ød1 ≤ 12,00 | ± 0,20 | 254,50 < Ød1 ≤ 256,00 | ± 1,85 | |

| 12,00 < Ød1 ≤ 13,30 | ± 0,21 | 256,00 < Ød1 ≤ 258,00 | ± 1,86 | |

| 13,30 < Ød1 ≤ 14,80 | ± 0,22 | 258,00 < Ød1 ≤ 259,00 | ± 1,87 | |

| 14,80 < Ød1 ≤ 16,00 | ± 0,23 | 259,00 < Ød1 ≤ 261,00 | ± 1,88 | |

| 16,00 < Ød1 ≤ 17,30 | ± 0,24 | 261,00 < Ød1 ≤ 263,00 | ± 1,89 | |

| 17,30 < Ød1 ≤ 18,72 | ± 0,25 | 263,00 < Ød1 ≤ 264,00 | ± 1,90 | |

| 18,72 < Ød1 ≤ 20,22 | ± 0,26 | 264,00 < Ød1 ≤ 266,00 | ± 1,91 | |

| 20,22 < Ød1 ≤ 21,50 | ± 0,27 | 266,00 < Ød1 ≤ 267,00 | ± 1,92 | |

| 21,50 < Ød1 ≤ 23,00 | ± 0,28 | 267,00 < Ød1 ≤ 269,00 | ± 1,93 | |

| 23,00 < Ød1 ≤ 24,20 | ± 0,29 | 269,00 < Ød1 ≤ 270,00 | ± 1,94 | |

| 24,20 < Ød1 ≤ 25,50 | ± 0,30 | 270,00 < Ød1 ≤ 272,00 | ± 1,95 | |

| 25,50 < Ød1 ≤ 27,00 | ± 0,31 | 272,00 < Ød1 ≤ 273,00 | ± 1,96 | |

| 27,00 < Ød1 ≤ 28,24 | ± 0,32 | 273,00 < Ød1 ≤ 274,50 | ± 1,97 | |

| 28,24 < Ød1 ≤ 29,70 | ± 0,33 | 274,50 < Ød1 ≤ 276,00 | ± 1,98 | |

| 29,70 < Ød1 ≤ 31,12 | ± 0,34 | 276,00 < Ød1 ≤ 278,00 | ± 1,99 | |

| 31,12 < Ød1 ≤ 32,50 | ± 0,35 | 278,00 < Ød1 ≤ 279,30 | ± 2,00 | |

| 32,50 < Ød1 ≤ 34,00 | ± 0,36 | 279,30 < Ød1 ≤ 281,00 | ± 2,01 | |

| 34,00 < Ød1 ≤ 35,20 | ± 0,37 | 281,00 < Ød1 ≤ 283,00 | ± 2,02 | |

| 35,20 < Ød1 ≤ 37,00 | ± 0,38 | 283,00 < Ød1 ≤ 284,00 | ± 2,03 | |

| 37,00 < Ød1 ≤ 38,00 | ± 0,39 | 284,00 < Ød1 ≤ 286,00 | ± 2,04 | |

| 38,00 < Ød1 ≤ 39,40 | ± 0,40 | 286,00 < Ød1 ≤ 287,00 | ± 2,05 | |

| 39,40 < Ød1 ≤ 40,87 | ± 0,41 | 287,00 < Ød1 ≤ 289,00 | ± 2,06 | |

| 40,87 < Ød1 ≤ 42,30 | ± 0,42 | 289,00 < Ød1 ≤ 290,00 | ± 2,07 | |

| 42,30 < Ød1 ≤ 43,70 | ± 0,43 | 290,00 < Ød1 ≤ 291,47 | ± 2,08 | |

| 43,70 < Ød1 ≤ 45,30 | ± 0,44 | 291,47 < Ød1 ≤ 293,00 | ± 2,09 | |

| 45,30 < Ød1 ≤ 46,99 | ± 0,45 | 293,00 < Ød1 ≤ 295,00 | ± 2,10 | |

| 46,99 < Ød1 ≤ 48,00 | ± 0,46 | 295,00 < Ød1 ≤ 297,00 | ± 2,11 | |

| 48,00 < Ød1 ≤ 49,30 | ± 0,47 | 297,00 < Ød1 ≤ 297,80 | ± 2,12 | |

| 49,30 < Ød1 ≤ 50,80 | ± 0,48 | 297,80 < Ød1 ≤ 299,30 | ± 2,13 | |

| 50,80 < Ød1 ≤ 52,30 | ± 0,49 | 299,30 < Ød1 ≤ 301,00 | ± 2,14 | |

| 52,30 < Ød1 ≤ 53,57 | ± 0,50 | 301,00 < Ød1 ≤ 303,00 | ± 2,15 | |

| 53,57 < Ød1 ≤ 55,00 | ± 0,51 | 303,00 < Ød1 ≤ 304,00 | ± 2,16 | |

| 55,00 < Ød1 ≤ 56,52 | ± 0,52 | 304,00 < Ød1 ≤ 306,00 | ± 2,17 | |

| 56,52 < Ød1 ≤ 58,00 | ± 0,53 | 306,00 < Ød1 ≤ 307,00 | ± 2,18 | |

| 58,00 < Ød1 ≤ 59,30 | ± 0,54 | 307,00 < Ød1 ≤ 309,00 | ± 2,19 | |

| 59,30 < Ød1 ≤ 61,00 | ± 0,55 | 309,00 < Ød1 ≤ 310,50 | ± 2,20 | |

| 61,00 < Ød1 ≤ 62,30 | ± 0,56 | 310,50 < Ød1 ≤ 312,00 | ± 2,21 | |

| 62,30 < Ød1 ≤ 64,00 | ± 0,57 | 312,00 < Ød1 ≤ 314,00 | ± 2,22 | |

| 64,00 < Ød1 ≤ 65,10 | ± 0,58 | 314,00 < Ød1 ≤ 315,00 | ± 2,23 | |

| 65,10 < Ød1 ≤ 66,60 | ± 0,59 | 315,00 < Ød1 ≤ 316,87 | ± 2,24 | |

| 66,60 < Ød1 ≤ 67,95 | ± 0,60 | 316,87 < Ød1 ≤ 318,00 | ± 2,25 | |

| 67,95 < Ød1 ≤ 69,40 | ± 0,61 | 318,00 < Ød1 ≤ 319,50 | ± 2,26 | |

| 69,40 < Ød1 ≤ 71,00 | ± 0,62 | 319,50 < Ød1 ≤ 321,50 | ± 2,27 | |

| 71,00 < Ød1 ≤ 72,39 | ± 0,63 | 321,50 < Ød1 ≤ 323,00 | ± 2,28 | |

| 72,39 < Ød1 ≤ 74,00 | ± 0,64 | 323,00 < Ød1 ≤ 325,00 | ± 2,29 | |

| 74,00 < Ød1 ≤ 75,57 | ± 0,65 | 325,00 < Ød1 ≤ 326,00 | ± 2,30 | |

| 75,57 < Ød1 ≤ 77,00 | ± 0,66 | 326,00 < Ød1 ≤ 328,00 | ± 2,31 | |

| 77,00 < Ød1 ≤ 78,50 | ± 0,67 | 328,00 < Ød1 ≤ 329,00 | ± 2,32 | |

| 78,50 < Ød1 ≤ 79,60 | ± 0,68 | 329,00 < Ød1 ≤ 331,00 | ± 2,33 | |

| 79,60 < Ød1 ≤ 81,00 | ± 0,69 | 331,00 < Ød1 ≤ 332,00 | ± 2,34 | |

| 81,00 < Ød1 ≤ 82,50 | ± 0,70 | 332,00 < Ød1 ≤ 334,00 | ± 2,35 | |

| 82,50 < Ød1 ≤ 84,00 | ± 0,71 | 334,00 < Ød1 ≤ 335,90 | ± 2,36 | |

| 84,00 < Ød1 ≤ 86,00 | ± 0,72 | 335,90 < Ød1 ≤ 337,00 | ± 2,37 | |

| 86,00 < Ød1 ≤ 87,00 | ± 0,73 | 337,00 < Ød1 ≤ 339,00 | ± 2,38 | |

| 87,00 < Ød1 ≤ 88,49 | ± 0,74 | 339,00 < Ød1 ≤ 340,00 | ± 2,39 | |

| 88,49 < Ød1 ≤ 90,00 | ± 0,75 | 340,00 < Ød1 ≤ 342,00 | ± 2,40 | |

| 90,00 < Ød1 ≤ 91,44 | ± 0,76 | 342,00 < Ød1 ≤ 343,00 | ± 2,41 | |

| 91,44 < Ød1 ≤ 93,00 | ± 0,77 | 343,00 < Ød1 ≤ 345,00 | ± 2,42 | |

| 93,00 < Ød1 ≤ 94,30 | ± 0,78 | 345,00 < Ød1 ≤ 347,00 | ± 2,43 | |

| 94,30 < Ød1 ≤ 96,00 | ± 0,79 | 347,00 < Ød1 ≤ 348,00 | ± 2,44 | |

| 96,00 < Ød1 ≤ 97,50 | ± 0,80 | 348,00 < Ød1 ≤ 350,00 | ± 2,45 | |

| 97,50 < Ød1 ≤ 99,00 | ± 0,81 | 350,00 < Ød1 ≤ 351,00 | ± 2,46 | |

| 99,00 < Ød1 ≤ 100,50 | ± 0,82 | 351,00 < Ød1 ≤ 353,00 | ± 2,47 | |

| 100,50 < Ød1 ≤ 101,60 | ± 0,83 | 353,00 < Ød1 ≤ 354,00 | ± 2,48 | |

| 101,60 < Ød1 ≤ 103,00 | ± 0,84 | 354,00 < Ød1 ≤ 356,00 | ± 2,49 | |

| 103,00 < Ød1 ≤ 104,50 | ± 0,85 | 356,00 < Ød1 ≤ 358,00 | ± 2,50 | |

| 104,50 < Ød1 ≤ 106,00 | ± 0,86 | 358,00 < Ød1 ≤ 359,00 | ± 2,51 | |

| 106,00 < Ød1 ≤ 107,54 | ± 0,87 | 359,00 < Ød1 ≤ 361,00 | ± 2,52 | |

| 107,54 < Ød1 ≤ 109,00 | ± 0,88 | 361,00 < Ød1 ≤ 362,00 | ± 2,53 | |

| 109,00 < Ød1 ≤ 110,49 | ± 0,89 | 362,00 < Ød1 ≤ 364,00 | ± 2,54 | |

| 110,49 < Ød1 ≤ 112,00 | ± 0,90 | 364,00 < Ød1 ≤ 365,00 | ± 2,55 | |

| 112,00 < Ød1 ≤ 113,67 | ± 0,91 | 365,00 < Ød1 ≤ 367,00 | ± 2,56 | |

| 113,67 < Ød1 ≤ 115,00 | ± 0,92 | 367,00 < Ød1 ≤ 369,00 | ± 2,57 | |

| 115,00 < Ød1 ≤ 116,84 | ± 0,93 | 369,00 < Ød1 ≤ 370,00 | ± 2,58 | |

| 116,84 < Ød1 ≤ 118,00 | ± 0,94 | 370,00 < Ød1 ≤ 372,00 | ± 2,59 | |

| 118,00 < Ød1 ≤ 119,30 | ± 0,95 | 372,00 < Ød1 ≤ 373,00 | ± 2,60 | |

| 119,30 < Ød1 ≤ 121,00 | ± 0,96 | 373,00 < Ød1 ≤ 374,50 | ± 2,61 | |

| 121,00 < Ød1 ≤ 123,00 | ± 0,97 | 374,50 < Ød1 ≤ 376,00 | ± 2,62 | |

| 123,00 < Ød1 ≤ 123,83 | ± 0,98 | 376,00 < Ød1 ≤ 378,00 | ± 2,63 | |

| 123,83 < Ød1 ≤ 126,00 | ± 0,99 | 378,00 < Ød1 ≤ 379,30 | ± 2,64 | |

| 126,00 < Ød1 ≤ 126,72 | ± 1,00 | 379,30 < Ød1 ≤ 381,00 | ± 2,65 | |

| 126,72 < Ød1 ≤ 129,00 | ± 1,01 | 381,00 < Ød1 ≤ 383,00 | ± 2,66 | |

| 129,00 < Ød1 ≤ 129,77 | ± 1,02 | 383,00 < Ød1 ≤ 384,00 | ± 2,67 | |

| 129,77 < Ød1 ≤ 131,50 | ± 1,03 | 384,00 < Ød1 ≤ 386,00 | ± 2,68 | |

| 131,50 < Ød1 ≤ 132,72 | ± 1,04 | 386,00 < Ød1 ≤ 387,00 | ± 2,69 | |

| 132,72 < Ød1 ≤ 134,30 | ± 1,05 | 387,00 < Ød1 ≤ 389,00 | ± 2,70 | |

| 134,30 < Ød1 ≤ 135,76 | ± 1,06 | 389,00 < Ød1 ≤ 391,00 | ± 2,71 | |

| 135,76 < Ød1 ≤ 138,00 | ± 1,07 | 391,00 < Ød1 ≤ 392,00 | ± 2,72 | |

| 138,00 < Ød1 ≤ 138,94 | ± 1,08 | 392,00 < Ød1 ≤ 394,00 | ± 2,73 | |

| 138,94 < Ød1 ≤ 140,50 | ± 1,09 | 394,00 < Ød1 ≤ 395,00 | ± 2,74 | |

| 140,50 < Ød1 ≤ 142,00 | ± 1,10 | 395,00 < Ød1 ≤ 397,00 | ± 2,75 | |

| 142,00 < Ød1 ≤ 144,00 | ± 1,11 | 397,00 < Ød1 ≤ 398,00 | ± 2,76 | |

| 144,00 < Ød1 ≤ 145,00 | ± 1,12 | 398,00 < Ød1 ≤ 400,00 | ± 2,77 | |

| 145,00 < Ød1 ≤ 147,00 | ± 1,13 | 400,00 < Ød1 ≤ 402,00 | ± 2,78 | |

| 147,00 < Ød1 ≤ 148,00 | ± 1,14 | 402,00 < Ød1 ≤ 403,00 | ± 2,79 | |

| 148,00 < Ød1 ≤ 149,23 | ± 1,15 | 403,00 < Ød1 ≤ 405,00 | ± 2,80 | |

| 149,23 < Ød1 ≤ 151,00 | ± 1,16 | 405,00 < Ød1 ≤ 406,00 | ± 2,81 | |

| 151,00 < Ød1 ≤ 152,50 | ± 1,17 | 406,00 < Ød1 ≤ 408,00 | ± 2,82 | |

| 152,50 < Ød1 ≤ 154,00 | ± 1,18 | 408,00 < Ød1 ≤ 409,00 | ± 2,83 | |

| 154,00 < Ød1 ≤ 155,50 | ± 1,19 | 409,00 < Ød1 ≤ 411,00 | ± 2,84 | |

| 155,50 < Ød1 ≤ 157,00 | ± 1,20 | 411,00 < Ød1 ≤ 413,00 | ± 2,85 | |

| 157,00 < Ød1 ≤ 158,34 | ± 1,21 | 413,00 < Ød1 ≤ 414,00 | ± 2,86 | |

| 158,34 < Ød1 ≤ 160,00 | ± 1,22 | 414,00 < Ød1 ≤ 416,00 | ± 2,87 | |

| 160,00 < Ød1 ≤ 161,30 | ± 1,23 | 416,00 < Ød1 ≤ 417,00 | ± 2,88 | |

| 161,30 < Ød1 ≤ 163,00 | ± 1,24 | 417,00 < Ød1 ≤ 419,00 | ± 2,89 | |

| 163,00 < Ød1 ≤ 164,30 | ± 1,25 | 419,00 < Ød1 ≤ 421,00 | ± 2,90 | |

| 164,30 < Ød1 ≤ 166,00 | ± 1,26 | 421,00 < Ød1 ≤ 422,00 | ± 2,91 | |

| 166,00 < Ød1 ≤ 167,50 | ± 1,27 | 422,00 < Ød1 ≤ 424,00 | ± 2,92 | |

| 167,50 < Ød1 ≤ 169,00 | ± 1,28 | 424,00 < Ød1 ≤ 425,00 | ± 2,93 | |

| 169,00 < Ød1 ≤ 170,69 | ± 1,29 | 425,00 < Ød1 ≤ 427,00 | ± 2,94 | |

| 170,69 < Ød1 ≤ 172,00 | ± 1,30 | 427,00 < Ød1 ≤ 428,00 | ± 2,95 | |

| 172,00 < Ød1 ≤ 173,87 | ± 1,31 | 428,00 < Ød1 ≤ 430,00 | ± 2,96 | |

| 173,87 < Ød1 ≤ 175,00 | ± 1,32 | 430,00 < Ød1 ≤ 432,00 | ± 2,97 | |

| 175,00 < Ød1 ≤ 177,00 | ± 1,33 | 432,00 < Ød1 ≤ 433,00 | ± 2,98 | |

| 177,00 < Ød1 ≤ 178,00 | ± 1,34 | 433,00 < Ød1 ≤ 435,00 | ± 2,99 | |

| 178,00 < Ød1 ≤ 179,50 | ± 1,35 | 435,00 < Ød1 ≤ 436,00 | ± 3,00 | |

| 179,50 < Ød1 ≤ 181,00 | ± 1,36 | 436,00 < Ød1 ≤ 438,00 | ± 3,01 | |

| 181,00 < Ød1 ≤ 182,50 | ± 1,37 | 438,00 < Ød1 ≤ 439,30 | ± 3,02 | |

| 182,50 < Ød1 ≤ 184,00 | ± 1,38 | 439,30 < Ød1 ≤ 441,00 | ± 3,03 | |

| 184,00 < Ød1 ≤ 186,00 | ± 1,39 | 441,00 < Ød1 ≤ 443,00 | ± 3,04 | |

| 186,00 < Ød1 ≤ 187,00 | ± 1,40 | 443,00 < Ød1 ≤ 444,00 | ± 3,05 | |

| 187,00 < Ød1 ≤ 189,00 | ± 1,41 | 444,00 < Ød1 ≤ 446,00 | ± 3,06 | |

| 189,00 < Ød1 ≤ 190,00 | ± 1,42 | 446,00 < Ød1 ≤ 447,00 | ± 3,07 | |

| 190,00 < Ød1 ≤ 192,00 | ± 1,43 | 447,00 < Ød1 ≤ 449,00 | ± 3,08 | |

| 192,00 < Ød1 ≤ 193,00 | ± 1,44 | 449,00 < Ød1 ≤ 451,00 | ± 3,09 | |

| 193,00 < Ød1 ≤ 195,00 | ± 1,45 | 451,00 < Ød1 ≤ 452,00 | ± 3,10 | |

| 195,00 < Ød1 ≤ 196,22 | ± 1,46 | 452,00 < Ød1 ≤ 454,00 | ± 3,11 | |

| 196,22 < Ød1 ≤ 198,00 | ± 1,47 | 454,00 < Ød1 ≤ 455,00 | ± 3,12 | |

| 198,00 < Ød1 ≤ 199,10 | ± 1,48 | 455,00 < Ød1 ≤ 457,00 | ± 3,13 | |

| 199,10 < Ød1 ≤ 201,00 | ± 1,49 | 457,00 < Ød1 ≤ 459,00 | ± 3,14 | |

| 201,00 < Ød1 ≤ 202,57 | ± 1,50 | 459,00 < Ød1 ≤ 460,00 | ± 3,15 | |

| 202,57 < Ød1 ≤ 204,00 | ± 1,51 | 460,00 < Ød1 ≤ 462,00 | ± 3,16 | |

| 204,00 < Ød1 ≤ 206,00 | ± 1,52 | 462,00 < Ød1 ≤ 463,00 | ± 3,17 | |

| 206,00 < Ød1 ≤ 207,00 | ± 1,53 | 463,00 < Ød1 ≤ 465,00 | ± 3,18 | |

| 207,00 < Ød1 ≤ 208,50 | ± 1,54 | 465,00 < Ød1 ≤ 467,00 | ± 3,19 | |

| 208,50 < Ød1 ≤ 210,00 | ± 1,55 | 467,00 < Ød1 ≤ 468,00 | ± 3,20 | |

| 210,00 < Ød1 ≤ 212,00 | ± 1,56 | 468,00 < Ød1 ≤ 470,00 | ± 3,21 | |

| 212,00 < Ød1 ≤ 213,00 | ± 1,57 | 470,00 < Ød1 ≤ 471,00 | ± 3,22 | |

| 213,00 < Ød1 ≤ 214,50 | ± 1,58 | 471,00 < Ød1 ≤ 473,00 | ± 3,23 | |

| 214,50 < Ød1 ≤ 216,00 | ± 1,59 | 473,00 < Ød1 ≤ 475,00 | ± 3,24 | |

| 216,00 < Ød1 ≤ 218,00 | ± 1,60 | 475,00 < Ød1 ≤ 476,00 | ± 3,25 | |

| 218,00 < Ød1 ≤ 219,00 | ± 1,61 | 476,00 < Ød1 ≤ 478,00 | ± 3,26 | |

| 219,00 < Ød1 ≤ 221,00 | ± 1,62 | 478,00 < Ød1 ≤ 479,00 | ± 3,27 | |

| 221,00 < Ød1 ≤ 222,00 | ± 1,63 | 479,00 < Ød1 ≤ 481,00 | ± 3,28 | |

| 222,00 < Ød1 ≤ 224,00 | ± 1,64 | 481,00 < Ød1 ≤ 482,00 | ± 3,29 | |

| 224,00 < Ød1 ≤ 226,00 | ± 1,65 | 482,00 < Ød1 ≤ 484,00 | ± 3,30 | |

| 226,00 < Ød1 ≤ 227,00 | ± 1,66 | 484,00 < Ød1 ≤ 486,00 | ± 3,31 | |

| 227,00 < Ød1 ≤ 228,19 | ± 1,67 | 486,00 < Ød1 ≤ 487,00 | ± 3,32 | |

| 228,19 < Ød1 ≤ 230,00 | ± 1,68 | 487,00 < Ød1 ≤ 489,00 | ± 3,33 | |

| 230,00 < Ød1 ≤ 232,00 | ± 1,69 | 489,00 < Ød1 ≤ 490,00 | ± 3,34 | |

| 232,00 < Ød1 ≤ 233,00 | ± 1,70 | 490,00 < Ød1 ≤ 492,00 | ± 3,35 | |

| 233,00 < Ød1 ≤ 234,32 | ± 1,71 | 492,00 < Ød1 ≤ 494,00 | ± 3,36 | |

| 234,32 < Ød1 ≤ 236,00 | ± 1,72 | 494,00 < Ød1 ≤ 495,00 | ± 3,37 | |

| 236,00 < Ød1 ≤ 237,50 | ± 1,73 | 495,00 < Ød1 ≤ 497,00 | ± 3,38 | |

| 237,50 < Ød1 ≤ 239,00 | ± 1,74 | 497,00 < Ød1 ≤ 498,00 | ± 3,39 | |

| 239,00 < Ød1 ≤ 240,67 | ± 1,75 | 498,00 < Ød1 ≤ 500,00 | ± 3,40 | |

| 240,67 < Ød1 ≤ 242,00 | ± 1,76 | 500,00 < Ød1 ≤ 504,00 | ± 3,41 |

The tolerances on standardised cross-sections Ød2 set out in the table below relate to standard ISO 3601-1:2008.

| Cross-section Ød2 |

Tolerances |

|---|---|

| 1,78 | ± 0,08 |

| 2,62 | ± 0,09 |

| 3,53 | ± 0,10 |

| 5,33 | ± 0,13 |

| 6,99 | ± 0,15 |

The tolerances on non-standardised cross-sections Ød2 set out in the table below relate to standard ISO 3601-1:2008.

| Cross-section Ød2 |

Tolerances |

|---|---|

| 0,80 < S ≤ 2,25 | ± 0,08 |

| 2,25 < S ≤ 3,15 | ± 0,09 |

| 3,15 < S ≤ 4,50 | ± 0,10 |

| 4,50 < S ≤ 6,30 | ± 0,13 |

| 6,30 < S ≤ 8,40 | ± 0,15 |

| 8,40 < S ≤ 10,00 | ± 0,21 |

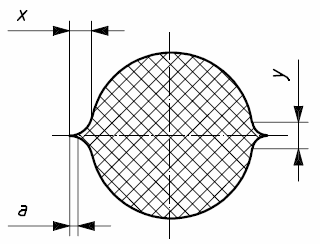

The O'Ring ensures sealing under radial deformation at the cross-section Ød2.

For rod sealing (inside sealing), the dimension of the O'Ring should be selected so that the outside diameter of the O'Ring is 0.5% to 5% greater than the groove diameter Ød6.

For piston sealing (outside sealing), the dimension of the O'Ring should be selected so that the inside diameter Ød1 of the O'Ring is 0.5% to 8% smaller than the groove diameter Ød3.

The table below sets out the tightening values (min and max) according to the cross-section Ød2

The table below sets out the design recommendations - Rectangular groove - Radial static pneumatic and hydraulic sealing.

| Cross-section Ød2 |

Groove depth t 0/+0,05 |

Groove width L1 0/+0,20 |

Groove radius R1 |

|---|---|---|---|

| 1,78 | 1,30 | 2,70 | 0,30 |

| 1,80 | 1,30 | 2,70 | 0,30 |

| 1,83 | 1,35 | 2,70 | 0,30 |

| 1,90 | 1,40 | 2,80 | 0,30 |

| 1,98 | 1,50 | 2,80 | 0,30 |

| 2,00 | 1,50 | 2,90 | 0,30 |

| 2,08 | 1,55 | 3,00 | 0,30 |

| 2,10 | 1,55 | 3,00 | 0,30 |

| 2,20 | 1,60 | 3,20 | 0,30 |

| 2,21 | 1,60 | 3,20 | 0,30 |

| 2,30 | 1,75 | 3,20 | 0,30 |

| 2,34 | 1,75 | 3,30 | 0,30 |

| 2,40 | 1,80 | 3,40 | 0,30 |

| 2,46 | 1,85 | 3,50 | 0,30 |

| 2,50 | 1,90 | 3,50 | 0,30 |

| 2,62 | 2,00 | 3,60 | 0,30 |

| 2,65 | 2,00 | 3,70 | 0,30 |

| 2,70 | 2,05 | 3,80 | 0,30 |

| 2,80 | 2,10 | 4,30 | 0,60 |

| 2,92 | 2,20 | 4,50 | 0,60 |

| 2,95 | 2,20 | 4,50 | 0,60 |

| 3,00 | 2,30 | 4,50 | 0,60 |

| 3,10 | 2,40 | 4,60 | 0,60 |

| 3,15 | 2,45 | 4,60 | 0,60 |

| 3,50 | 2,70 | 5,10 | 0,60 |

| 3,53 | 2,70 | 5,10 | 0,60 |

| 3,55 | 2,70 | 5,20 | 0,60 |

| 3,60 | 2,80 | 5,20 | 0,60 |

| 4,00 | 3,10 | 5,60 | 0,60 |

| 4,50 | 3,55 | 6,20 | 0,60 |

| 5,00 | 4,00 | 6,70 | 0,60 |

| 5,30 | 4,30 | 6,90 | 0,60 |

| 5,33 | 4,30 | 7,10 | 0,60 |

| 5,50 | 4,50 | 7,10 | 0,60 |

| 5,70 | 4,60 | 7,40 | 0,60 |

| 6,00 | 4,90 | 7,80 | 0,60 |

| 6,50 | 5,40 | 8,70 | 1,00 |

| 6,99 | 5,80 | 9,30 | 1,00 |

| 7,00 | 5,80 | 9,50 | 1,00 |

| 7,50 | 6,30 | 9,70 | 1,00 |

| 8,00 | 6,70 | 10,20 | 1,00 |

| 8,40 | 7,10 | 10,50 | 1,00 |

| 9,00 | 7,65 | 12,30 | 1,50 |

| 9,50 | 8,20 | 12,70 | 1,50 |

| 10,00 | 8,60 | 15,10 | 2,00 |

| 12,00 | 10,30 | 17,00 | 2,00 |

These values are provided for information purposes only. We recommend refining your design using our O'Ring calculator, which is available free in the "Tools" tab on the website.

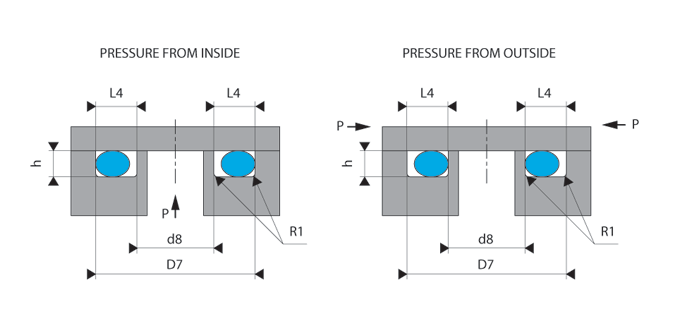

Flange and cover sealing is generally ensured by an O'Ring that is subject to axial deformation. The groove dimensions are determined according to the direction of the pressure.

When the pressure is directed from the outside in, the inside diameter Ød1 of the O'Ring must be 0.5% to 3.5% less than the inside diameter of the groove.

On the other hand, when the pressure is directed from the inside out, the outside diameter of the O'Ring must be 0.5% to 3.5% greater than the outside diameter of the groove.

The table below sets out the tightening values (min and max) according to the cross-section Ød2

The table below sets out the design recommendations - Rectangular groove - Axial static sealing

| Cross-section Ød2 |

Groove depth h 0/+0,05 |

Groove width L4 0/+0,20 |

Radius R1 |

|---|---|---|---|

| 1,78 | 1,30 | 2,70 | 0,30 |

| 1,80 | 1,30 | 2,80 | 0,30 |

| 1,83 | 1,35 | 2,80 | 0,30 |

| 1,90 | 1,40 | 2,90 | 0,30 |

| 1,98 | 1,45 | 3,00 | 0,30 |

| 2,00 | 1,45 | 3,00 | 0,30 |

| 2,08 | 1,50 | 3,10 | 0,30 |

| 2,10 | 1,50 | 3,20 | 0,30 |

| 2,20 | 1,60 | 3,30 | 0,30 |

| 2,21 | 1,60 | 3,30 | 0,30 |

| 2,30 | 1,65 | 3,40 | 0,30 |

| 2,34 | 1,70 | 3,40 | 0,30 |

| 2,40 | 1,75 | 3,50 | 0,30 |

| 2,46 | 1,80 | 3,60 | 0,30 |

| 2,50 | 1,80 | 3,70 | 0,30 |

| 2,62 | 1,95 | 3,70 | 0,30 |

| 2,65 | 2,00 | 3,70 | 0,30 |

| 2,70 | 2,05 | 3,80 | 0,30 |

| 2,80 | 2,15 | 4,00 | 0,60 |

| 2,92 | 2,20 | 4,20 | 0,60 |

| 2,95 | 2,25 | 4,20 | 0,60 |

| 3,00 | 2,30 | 4,30 | 0,60 |

| 3,10 | 2,40 | 4,40 | 0,60 |

| 3,15 | 2,40 | 4,50 | 0,60 |

| 3,50 | 2,70 | 4,80 | 0,60 |

| 3,53 | 2,75 | 4,80 | 0,60 |

| 3,55 | 2,80 | 4,80 | 0,60 |

| 3,60 | 2,85 | 4,90 | 0,60 |

| 4,00 | 3,20 | 5,30 | 0,60 |

| 4,50 | 3,60 | 5,80 | 0,60 |

| 5,00 | 4,00 | 6,50 | 0,60 |

| 5,30 | 4,20 | 6,90 | 0,60 |

| 5,33 | 4,30 | 6,80 | 0,60 |

| 5,50 | 4,50 | 6,90 | 0,60 |

| 5,70 | 4,70 | 7,10 | 0,60 |

| 6,00 | 4,90 | 7,40 | 0,60 |

| 6,50 | 5,30 | 8,40 | 1,00 |

| 6,99 | 5,80 | 8,80 | 1,00 |

| 7,00 | 5,80 | 8,80 | 1,00 |

| 7,50 | 6,30 | 9,20 | 1,00 |

| 8,00 | 6,70 | 9,80 | 1,00 |

| 8,40 | 7,20 | 10,00 | 1,00 |

| 9,00 | 7,60 | 11,50 | 1,50 |

| 9,50 | 8,00 | 12,10 | 1,50 |

| 10,00 | 8,70 | 13,10 | 2,00 |

| 12,00 | 10,40 | 15,30 | 2,00 |

These values are provided for information purposes only. We recommend refining your design using our O'Ring calculator, which is available free in the "Tools" tab on the website.

O'Rings can be used as sealing components for hydraulic applications in linear motion. However, they have an average efficiency and are only suitable for relatively low travel and frequencies. Other seal profiles are prioritised for such applications (see the hydraulic seals range).

For rod sealing (inside sealing), the dimension of the O'Ring should be selected so that the outside diameter of the O'Ring is 0.5% to 5% greater than the groove diameter Ød6.

For piston sealing (outside sealing), the dimension of the O'Ring should be selected so that the inside diameter Ød1 of the O'Ring is 0.5% to 5% smaller than the groove diameter Ød3.

The table below sets out the tightening values (min and max) according to the cross-section Ød2

The table below sets out the design recommendations - Rectangular groove - Dynamic hydraulic sealing for linear movements

| Cross-section Ød2 |

Groove depth t 0/+0,05 |

Groove width L1 0/+0,20 |

Groove radius R1 |

|---|---|---|---|

| 1,78 | 1,35 | 2,60 | 0,30 |

| 1,80 | 1,35 | 2,60 | 0,30 |

| 1,83 | 1,40 | 2,60 | 0,30 |

| 1,90 | 1,45 | 2,70 | 0,30 |

| 1,98 | 1,50 | 2,80 | 0,30 |

| 2,00 | 1,55 | 2,80 | 0,30 |

| 2,08 | 1,60 | 2,90 | 0,30 |

| 2,10 | 1,60 | 2,90 | 0,30 |

| 2,20 | 1,70 | 3,00 | 0,30 |

| 2,21 | 1,70 | 3,00 | 0,30 |

| 2,30 | 1,80 | 3,10 | 0,30 |

| 2,34 | 1,85 | 3,20 | 0,30 |

| 2,40 | 1,90 | 3,20 | 0,30 |

| 2,46 | 1,95 | 3,30 | 0,30 |

| 2,50 | 1,95 | 3,40 | 0,30 |

| 2,62 | 2,05 | 3,50 | 0,30 |

| 2,65 | 2,10 | 3,50 | 0,30 |

| 2,70 | 2,15 | 3,60 | 0,30 |

| 2,80 | 2,25 | 4,00 | 0,60 |

| 2,92 | 2,35 | 4,20 | 0,60 |

| 2,95 | 2,35 | 4,20 | 0,60 |

| 3,00 | 2,40 | 4,30 | 0,60 |

| 3,10 | 2,50 | 4,40 | 0,60 |

| 3,15 | 2,55 | 4,50 | 0,60 |

| 3,50 | 2,85 | 4,90 | 0,60 |

| 3,53 | 2,85 | 4,90 | 0,60 |

| 3,55 | 2,90 | 4,90 | 0,60 |

| 3,60 | 2,95 | 4,90 | 0,60 |

| 4,00 | 3,25 | 5,40 | 0,60 |

| 4,50 | 3,70 | 5,90 | 0,60 |

| 5,00 | 4,10 | 6,60 | 0,60 |

| 5,30 | 4,40 | 6,80 | 0,60 |

| 5,33 | 4,40 | 6,80 | 0,60 |

| 5,50 | 4,65 | 6,80 | 0,60 |

| 5,70 | 4,80 | 7,10 | 0,60 |

| 6,00 | 5,10 | 7,40 | 0,60 |

| 6,50 | 5,50 | 8,60 | 1,00 |

| 6,99 | 5,90 | 9,20 | 1,00 |

| 7,00 | 5,90 | 9,20 | 1,00 |

| 7,50 | 6,50 | 9,50 | 1,00 |

| 8,00 | 7,00 | 9,90 | 1,00 |

| 8,40 | 7,30 | 10,30 | 1,00 |

| 9,00 | 7,80 | 11,20 | 1,50 |

| 9,50 | 8,10 | 11,90 | 1,50 |

| 10,00 | 8,80 | 12,00 | 2,00 |

| 12,00 | 10,60 | 14,30 | 2,00 |

These values are provided for information purposes only. We recommend refining your design using our O'Ring calculator, which is available free in the "Tools" tab on the website.

To make the tubes and rods, we recommend using non-porous steel or cast iron. For dynamic applications, brass and untreated stainless steel, as well as aluminium, are not as hard and are therefore not recommended, as they would be subjected to a lot of wear.

The roughness means that the sealing must be of a high quality. The surface roughness of grooves improves during alternating pressures.

| Type of application | Type of surface | Roughness Ra |

Roughness Rz |

Roughness |

|---|---|---|---|---|

| Radial - Static | Under non-pulsating pressure | |||

| Mating surface (rod and cylinder) | 1,6 µm | 6,3 µm | 10,0 µm | |

| Groove diameter and groove flanks | 1,6 µm | 6,3 µm | 10,0 µm | |

| Under pulsating pressure | ||||

| Mating surface (rod and cylinder) | 0,8 µm | 3,2 µm | 5,0 µm | |

| Groove diameter and groove flanks | 1,6 µm | 6,3 µm | 10,0 µm | |

| Radial - Dynamique | Mating surface (rod and cylinder) | 0,4 µm | 1,6 µm | 2,5 µm |

| Groove diameter and groove flanks | 0,8 µm | 3,2 µm | 5,0 µm | |

| Axial - Static | Clamping surface | 1,6 µm | 6,3 µm | 10,0 µm |

| Groove flanks | 1,6 µm | 6,3 µm | 10,0 µm | |

Given that the O'Rings are fitted pre-tightened, the chamfer lengths and rounded cutting edges must fit with the table below.

| Cross-section Ød2 |

Radius R1 |

Max radius R2 |

Chamfer C |

|

|---|---|---|---|---|

| 15° | 20° | |||

| 1,78 - 1,80 | 0,30 | 0,20 | 2,50 | 2,00 |

| 2,62 - 2,65 | 0,30 | 0,20 | 3,00 | 2,50 |

| 3,53 - 3,55 | 0,60 | 0,20 | 3,50 | 3,00 |

| 5,33 - 5,30 | 0,60 | 0,20 | 4,00 | 3,50 |

| 6,99 - 7,00 | 1,00 | 0,20 | 5,00 | 4,00 |

| 8,40 | 1,00 | 0,20 | 6,00 | 4,50 |

Quality criteria

The table below sets out the maximum limits for O'Ring appearance defects, in line with standard ISO 3601-3.

| Type of surface defect | Schematic presentation | Dimension limits | Maximum limits for defects on the cross-section Ød2 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| > 0,80 ≤ 2,25 | > 2,25 ≤ 3,15 | > 3,15 ≤ 4,50 | > 4,50 ≤ 6,30 | > 6,30 ≤ 8,40 | |||||

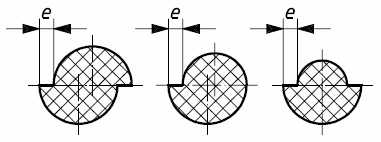

| Offset |  |

e | 0,08 | 0,10 | 0,13 | 0,15 | 0,15 | ||

| Flash |  |

x | 0,10 | 0,12 | 0,4 | 0,16 | 0,18 | ||

| y | 0,10 | 0,12 | 0,4 | 0,16 | 0,18 | ||||

| a | When the flash can be differentiated, it must not be greater than 0,07 mm. | ||||||||

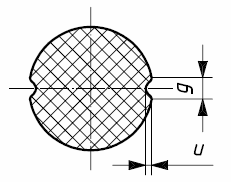

| Backrind |  |

g | 0,18 | 0,27 | 0,36 | 0,53 | 0,70 | ||

| u | 0,08 | 0,08 | 0,10 | 0,10 | 0,13 | ||||

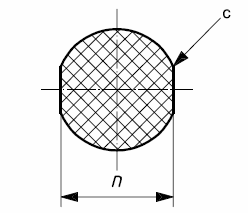

| Area of excessive trimming (radial tool marks not allowed) |  |

n | Trimming is allowed if the dimensionn is not less than the minimum diameter d2 of the O'Ring | ||||||

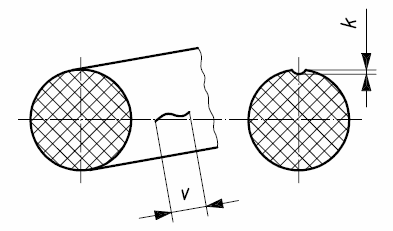

| Filling mark (folds must not be radial) |  |

v | 1,50 a | 1,50 a | 6,50 a | 6,50 a | 6,50 a | ||

| k | 0,08 | 0,08 | 0,08 | 0,08 | 0,08 | ||||

| Lack of material and tearing (including O'Ring tearing) |  |

w | 0,60 | 0,80 | 1,00 | 1,30 | 1,70 | ||

| t | 0,08 | 0,08 | 0,10 | 0,10 | 0,13 | ||||

| a: or 0.05 times the inside diameter of the O'Ring d1, taking the largest of the two values. | |||||||||

Only on request