FINITE ELEMENT ANALYSIS - SIMULATION

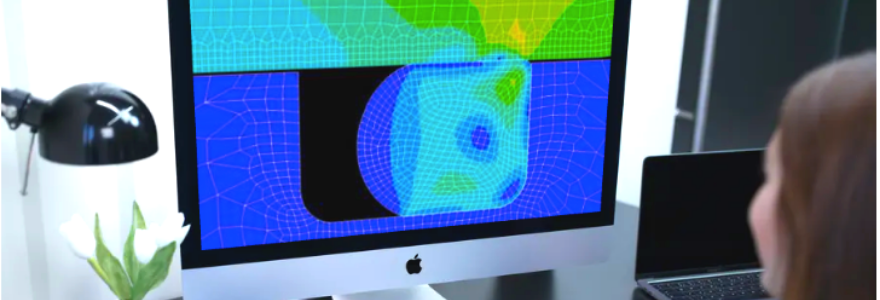

In order to accelerate and improve the development of new seal designs, France Joint uses finite element method numerical simulation mainly in non-linear.

To make the simulation as precise as possible, good characterisation of the material is essential.

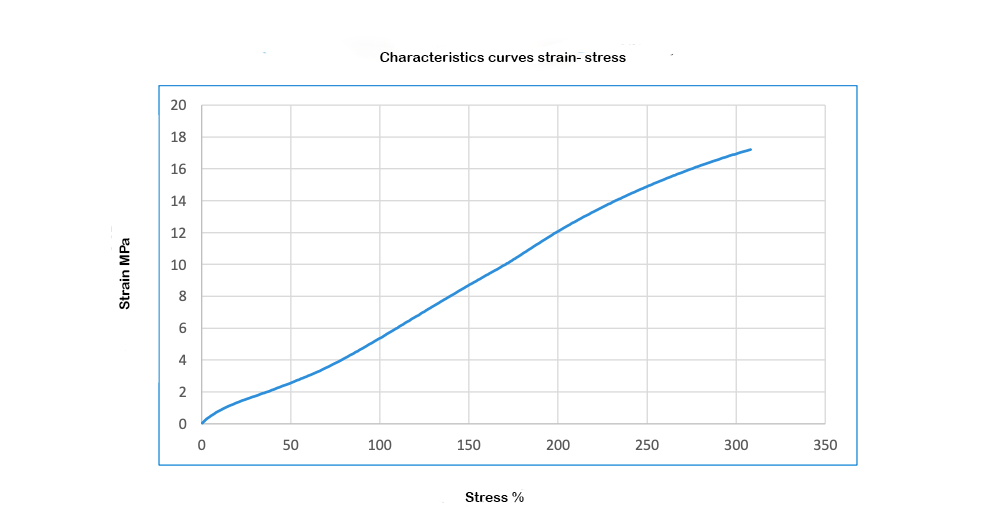

As a rule, metal parts have a linear relationship between stress and length changes up to a certain value, which makes analysis relatively simple. However, for elastomers, there is no linear relationship between stress and elongation and deformation of the material can very often exceed 100%.

Tensile and compression tests on specific test pieces are therefore done in our internal laboratory in order to determine the material’s relationship between its elongation and its stress for the purpose of determining hyper-elastic models for elastomers (Mooney-Rivlin, Ogden, etc…).

Below is an example of a stress – elongation characteristic curve

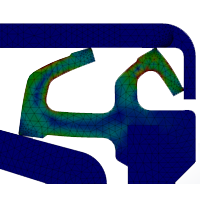

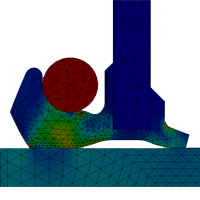

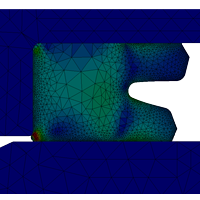

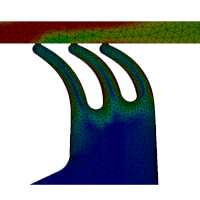

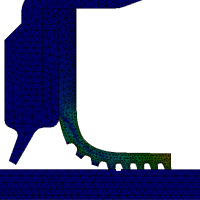

France Joint simulates its designs using tools such as ABAQUS and SOLIDWORKS SIMULATION, some examples of which are below:

|

|

|

| Cassette seal | Zoom - cassette seal | High pressure shaft seal |

|

|

|

| Lip seal - Hydraulic - Rod | Triple lip hub seal | Shaft seal - PTFE lip |