BECA 006/B

Description

The BECA 006/B profile is a roll of tape that can be cut to a specific length according to the customer's specification. Tapes or guide strips can be made with "integrated" embossing. The embossing is a set of lubricant pockets (also callsed teardrop structures), which improves the friction. Several types of cuts can be made.

Advantages

Substantial and improved lubrication conditions through the teardrop structures

Very good friction coefficient; no stick-slip effect

Good wear resistance; very long life

Increased absorption of foreign particles

Easy to fit

Good vibration absorption

Technical data

| Temperature | -60°C / +150°C (200°C) |

|---|---|

| Speed | 15 m/s |

| Medias | Mineral hydraulic oils |

| Max. compression resistance | 30 to 35 N/mm² |

| Radial loads in dynamic applications | 15 N/mm² at 25°C |

Applications

Agriculture

Food & Beverage

Shock absorbers

Maintenance

Dry applications

Injection presses

Pneumatics

Presses

Robotics

Standard cylinders

Materials

Bronze-filled PTFE

Carbon graphite-filled PTFE

Dimensions

Installation dimensions

Installation dimensions - Piston guide

| Piston guide | Thickness of the seal |

Gap | |||

|---|---|---|---|---|---|

| ISO 10766 | Bore diameter ØD1 H9 |

Groove diameter Ød1 h8 |

Groove width L1 0/+0.20 |

E | Z +/-0.50 |

| * | 8.0 - 20.0 | D1 - 3.10 | 2.50 | 1.55 | 1.00 |

| * | 10.0 - 50.0 | D1 - 3.10 | 4.00 | 1.55 | 1.00 |

| * | 16.0 - 140.0 | D1 - 5.00 | 5.60 | 2.50 | 1.25 |

| * | 60.0 - 220.0 | D1 - 5.00 | 9.70 | 2.50 | 1.25 |

| * | 130.0 - 400.0 | D1 - 5.00 | 15.00 | 2.50 | 1.25 |

| * | 280.0 - 999.9 | D1 - 5.00 | 25.00 | 2.50 | 1.25 |

| * | 280.0 - 999.9 | D1 - 8.00 | 25.00 | 4.00 | 2.00 |

Other dimensions are possible, not taking ISO 10766 into consideration. Please contact our experts.

Installation dimensions - Rod guide

| Rod guide | Thickness of the seal |

Gap | |||

|---|---|---|---|---|---|

| ISO 10766 | Rod diameter Ød1 f8/h9 |

Groove diameter ØD1 H8 |

Groove width L1 0/+0.20 |

E | Z +/-0.50 |

| * | 8.0 - 20.0 | d1 + 3.10 | 2.50 | 1.55 | 1.00 |

| * | 10.0 - 50.0 | d1 + 3.10 | 4.00 | 1.55 | 1.00 |

| * | 15.0 - 140.0 | d1 + 5.00 | 5.60 | 2.50 | 1.25 |

| * | 20.0 - 220.0 | d1 + 5.00 | 9.70 | 2.50 | 1.25 |

| * | 80.0 - 400.0 | d1 + 5.00 | 15.00 | 2.50 | 1.25 |

| * | 200.0 - 999.9 | d1 + 5.00 | 25.00 | 2.50 | 1.25 |

| * | 280.0 - 999.9 | d1 + 8.00 | 25.00 | 4.00 | 2.00 |

Other dimensions are possible, not taking ISO 10766 into consideration. Please contact our experts.

Materials

| Type of material | Service temperature | Characteristics | Contact surface area |

|---|---|---|---|

| Filled PTFE | -60°C / +150°C (+200°C) | Very good friction coefficient Good wear resistance Good extrusion resistance Excellent chemical inertia |

Steel, chrome steel, Cast iron |

Design guidelines

Guide sizing

The following formula calculates the linear length and accounts for the gap "Z" necessary at the ends of the tape after fitting. This gap "Z" offsets the thermal expansion under the effects of temperature, and prevents intermediate pressures and drag pressures in the system.

In the piston guide:

L (mm) = π x (ØD1 - E) - Z

In the rod guide:

L (mm) = π x (Ød1 + E) - Z

where:

L = Length of the guide tape (mm)

ØD1 = Piston diameter (mm)

Ød1 = Rod diameter (mm)

E = Thickness of the tape (mm)

Z = Gap after fitting

| L = Length of the tape L (mm) | Tolerances of L (mm) |

|---|---|

| ≤ 45.00 | ± 0.25 |

| > 45.00 | ± 0.40 |

| > 80.00 | ± 0.60 |

| > 100.00 | ± 0.80 |

| > 125.00 | ± 1.00 |

| > 150.00 | ± 1.20 |

| > 180.00 | ± 1.40 |

| > 215.00 | ± 1.60 |

| > 270.00 | ± 1.80 |

| > 330.00 | ± 2.00 |

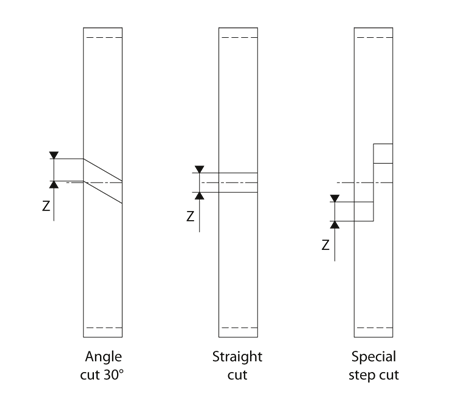

Types of cuts

The wear rings are made with a 30° angle cut as standard. Other types of cuts can be made on request, as shown in the diagram below.

Technical data

Extrusion gaps

| Bore diameter ØD1 Rod diameter Ød1 |

Min. Radial extrusion gap F/2 min |

Max. Radial extrusion gap F/2 max |

|---|---|---|

| 8.0 - 20.0 | 0.20 | 0.30 |

| 21.0 - 100.0 | 0.25 | 0.40 |

| 101.0 - 250.0 | 0.30 | 0.60 |

| 251.0 - 500.0 | 0.40 | 0.80 |

| 501.0 - 1000.0 | 0.50 | 1.10 |

| > 1000.0 | 0.60 | 1.20 |

Surface roughness

| Roughness | Dynamic surface area | Static surface area | Groove flanks |

|---|---|---|---|

| Ra | 0.05 - 0.2 µm | ≤ 1.6 µm | ≤ 3.2 µm |

| Rz | 0.4 - 1.6 µm | ≤ 6.3 µm | ≤ 10.0 µm |

| Rmax | 0.63 - 2.5 µm | ≤ 10.0 µm | ≤ 16.0 µm |

Radius

| Bore diameter ØD1 Rod diameter Ød1 |

Radius R1 |

|---|---|

| ≤ 250.0 | 0.20 |

| > 250.0 | 0.40 |

|

006.0321.5

|

3,20 | 3,00 | 1,50 |

|

006.0421.5

|

4,20 | 4,00 | 1,50 |

|

006.0631.5

|

6,30 | 6,10 | 1,50 |

|

006.0811.5

|

8,10 | 7,90 | 1,50 |

|

006.0971.5

|

9,70 | 9,50 | 1,50 |

|

006.1271.5

|

12,70 | 12,50 | 1,50 |

|

006.0151.5

|

15,00 | 14,80 | 1,50 |

|

006.0161.5

|

16,00 | 15,80 | 1,50 |

|

006.0201.5

|

20,00 | 19,50 | 1,50 |

|

006.0251.5

|

25,00 | 24,50 | 1,50 |

|

006.0301.5

|

30,00 | 29,50 | 1,50 |

|

006.0322.0

|

3,20 | 3,00 | 2,00 |

|

006.0422.0

|

4,20 | 4,00 | 2,00 |

|

006.0632.0

|

6,30 | 6,10 | 2,00 |

|

006.0812.0

|

8,10 | 7,90 | 2,00 |

|

006.0972.0

|

9,70 | 9,50 | 2,00 |

|

006.1272.0

|

12,70 | 12,50 | 2,00 |

|

006.0152.0

|

15,00 | 14,80 | 2,00 |

|

006.0202.0

|

20,00 | 19,50 | 2,00 |

|

006.0252.0

|

25,00 | 24,50 | 2,00 |

|

006.0302.0

|

30,00 | 29,50 | 2,00 |

|

006.0322.5

|

3,20 | 3,00 | 2,50 |

|

006.0422.5

|

4,20 | 4,00 | 2,50 |

|

006.0632.5

|

6,30 | 6,10 | 2,50 |

|

006.0812.5

|

8,10 | 7,90 | 2,50 |

|

006.0972.5

|

9,70 | 9,50 | 2,50 |

|

006.1272.5

|

12,70 | 12,50 | 2,50 |

|

006.0152.5

|

15,00 | 14,80 | 2,50 |

|

006.0202.5

|

20,00 | 19,50 | 2,50 |

|

006.0252.5

|

25,00 | 24,50 | 2,50 |

|

006.0302.5

|

30,00 | 29,50 | 2,50 |

|

006.0323.0

|

3,20 | 3,00 | 3,00 |

|

006.0423.0

|

4,20 | 4,00 | 3,00 |

|

006.0633.0

|

6,30 | 6,10 | 3,00 |

|

006.0813.0

|

8,10 | 7,90 | 3,00 |

|

006.0973.0

|

9,70 | 9,50 | 3,00 |

|

006.1273.0

|

12,70 | 12,50 | 3,00 |

|

006.0153.0

|

15,00 | 14,80 | 3,00 |

|

006.0203.0

|

20,00 | 19,50 | 3,00 |

|

006.0253.0

|

25,00 | 24,50 | 3,00 |

|

006.0303.0

|

30,00 | 29,50 | 3,00 |

|

006.3553.0

|

35,50 | 35,00 | 3,00 |

|

006.0634.0

|

6,30 | 6,10 | 4,00 |

|

006.0814.0

|

8,10 | 7,90 | 4,00 |

|

006.0974.0

|

9,70 | 9,50 | 4,00 |

|

006.1274.0

|

12,70 | 12,50 | 4,00 |

|

006.0154.0

|

15,00 | 14,80 | 4,00 |

|

006.0204.0

|

20,00 | 19,50 | 4,00 |

|

006.0254.0

|

25,00 | 24,50 | 4,00 |

|

006.0304.0

|

30,00 | 29,50 | 4,00 |