BECA 006 Piston

Description

The BECA 006 Piston profile is a machined guide ring with a 30° angle cut as standard, made from filled PTFE.

Advantages

Substantial and improved lubrication conditions through the tear structures

Very good friction coefficient; no stick-slip effect

Good wear resistance; very long life

Increased absorption of foreign particles

Good vibration absorption

Technical data

| Temperature | -60°C/+200°C |

|---|---|

| Pressure | * |

| Speed | 15.0 m/s |

| Medias | Mineral hydraulic oils |

| Max. compression resistance | 30 to 35 N/mm² |

| Radial loads in dynamic applications | 15 N/mm² at 25°C |

Applications

Aerospace

Aerospace

Military

Materials

Bronze-filled PTFE

Carbon-filled PTFE

Carbon graphite-filled PTFE

Dimensions

Installation dimensions

| Bore diameter ØD1 H10 |

Groove diameter Ød1 h8 |

Groove width L1 0/+0.25 |

Extrusion gaps F/2 max |

|---|---|---|---|

| 5.97 - 37.87 | D1 - 1.63 | 3.43 | 0.18 |

| 5.97 - 37.87 | D1 - 1.63 | 6.60 | 0.18 |

| 5.97 - 37.87 | D1 - 1.63 | 9.78 | 0.18 |

| 5.97 - 37.87 | D1 - 1.63 | 12.95 | 0.18 |

| 13.97 - 113.49 | D1 - 3.20 | 3.43 | 0.23 |

| 13.97 - 113.49 | D1 - 3.20 | 6.60 | 0.23 |

| 13.97 - 113.49 | D1 - 3.20 | 9.78 | 0.23 |

| 13.97 - 113.49 | D1 - 3.20 | 12.95 | 0.23 |

| 76.02 - 266.04 | D1 - 4.78 | 3.43 | 0.28 |

| 76.02 - 266.04 | D1 - 4.78 | 6.60 | 0.28 |

| 76.02 - 266.04 | D1 - 4.78 | 9.78 | 0.28 |

| 76.02 - 266.04 | D1 - 4.78 | 12.95 | 0.28 |

Materials

| Type of material | Service temperature | Characteristics | Contact surface area |

|---|---|---|---|

| Filled PTFE | -60°C / +150°C (+200°C) | Very good friction coefficient Good wear resistance Good extrusion resistance Excellent chemical inertia |

Steel, chrome steel, Cast iron |

Design guidelines

Guide sizing

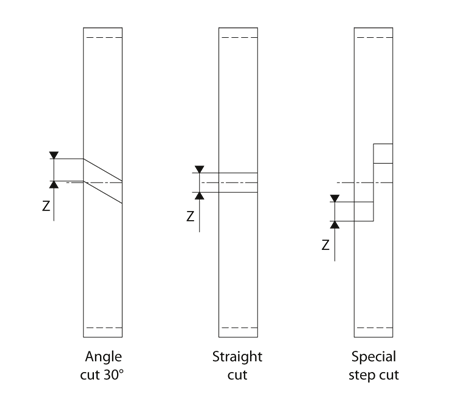

The following formulas calculate the height "H" of the wear ring in the piston or rod seal while taking the gap into account "Z" necessary at the ends of the ring after fitting. This gap "Z" offsets the thermal expansion under the effects of temperature, and prevents intermediate pressures and drag pressures in the system.

H = (F x f) / (ØD1 x Cr)

where:

H = Min. height of guide (mm)

F = Max. radial force (N)

f = Safety coefficient (we recommend 2)

ØD1 = Bore diameter (mm)

Cr = Permissible radial load in dynamic applications (N/mm²)

Types of cuts

Technical data

Surface roughness

| Roughness | Dynamic surface area | Static surface area | Groove flanks |

|---|---|---|---|

| Ra | 0.05 - 0.2 µm | ≤ 1.6 µm | ≤ 3.2 µm |

| Rz | 0.4 - 1.6 µm | ≤ 6.3 µm | ≤ 10.0 µm |

| Rmax | 0.63 - 2.5 µm | ≤ 10.0 µm | ≤ 16.0 µm |

Recommended radius of the groove diameter

| Bore diameter ØD1 |

Radius R1 max |

|---|---|

| ≤ 250.00 | 0.20 |

| > 250.00 | 0.40 |

Only on request