Nova Seal

Nova Seal : the high-performance seal for electric motors

Electricity changes everything, even sealing. Faster, hotter, more compact: electric motors require solutions that are up to the task. France Joint responds with Nova Seal: a high-speed, high-temperature seal.

E-mobility imposes new sealing standards

With the development of more compact and efficient electric powertrains, electric motors (e-Axles) are becoming increasingly common in electric and hybrid vehicles.

However, electric motors submit components to significant stresses: very high temperatures, extreme rotational speeds and use of aggressive lubricants.

Most of the seals currently used in these applications come from the thermal sector. They are not suited to these conditions and struggle to cope with these stresses.

The majority of seals currently used in these applications are made from the thermal sector. Poorly suited, they struggle to cope with these stresses.

Consequences :

- Overheating

- Leaks

- Loss of efficiency

- Reduced lifespan

It is in this context that we at France Joint have come up with the Nova Seal, a seal specially developed for new-generation electric motors. This high-speed sealing ring meets the needs of electric or hybrid vehicles.

Why is the electric motor a game changer?

E-Axle : an ultra-compact system subjected to excessive forces

The e-Axle is an ultra-compact subsystem that integrates the electric motor, gearbox, differential, drive shafts, and sometimes the inverter and cooling and lubrication circuits, all within a single housing. This integration reduces mechanical losses but introduces new sealing challenges.

This level of integration reduces mechanical losses but imposes new sealing constraints:

- Rotational speeds exceeding 25,000 rpm (≈ 40 m/s max) even more, well beyond the capabilities of traditional seals

- Extreme temperatures generated by the motors and integrated inverters (from -40°C to +180°C)

- Use of low-viscosity ATF fluids, often more chemically aggressive than conventional oils

In this high-stress environment, the seal plays a critical role:

- Separating sensitive mechanical and electronic components in the e-Axle system

- Withstanding wear, misalignments, pressure, and corrosive fluids

- Maintaining a consistent seal even at extreme rotational speeds

- Reducing friction, energy losses, and overheating

The limits of thermal seals in an electrical context

Seals manufactured for internal combustion engines are not optimized for the extreme demands of e-mobility. Their use quickly leads to excessive friction and can cause premature wear of the seals. Their use rapidly leads to excessive friction and can cause premature wear of the seals.

Nova Seal: a new generation of seals for e-mobility

A seal made for e-mobility

Nova Seal is designed to meet the extreme demands of electric mobility. It combines strength and precision to ensure optimal performance throughout the system's lifetime.

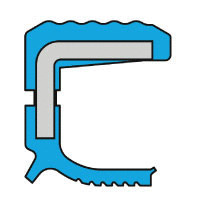

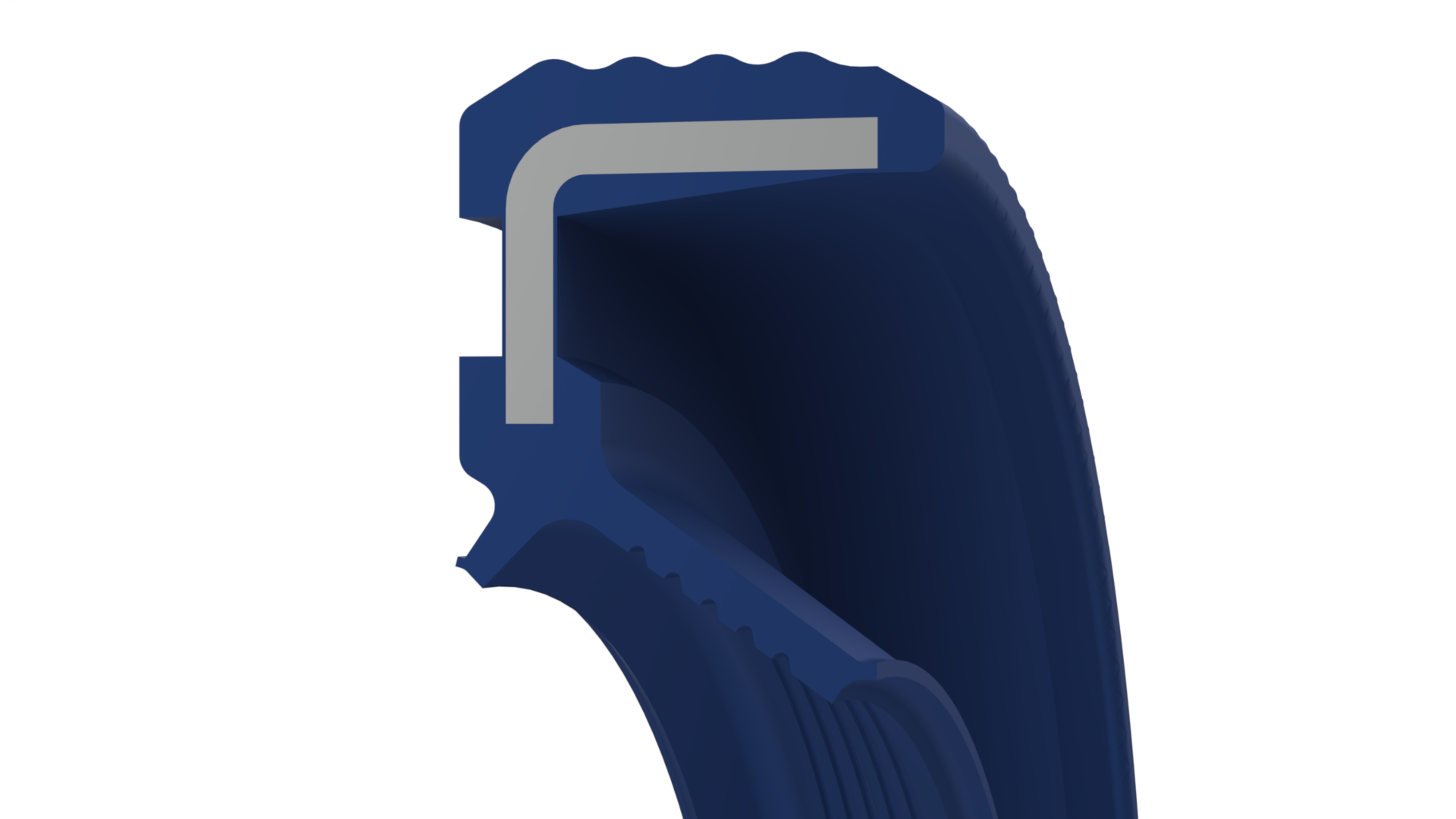

In terms of its geometry, this seal profile for electric or hybrid vehicles consists of:

- a flexible elastomer sealing strip

- a metal cage

- an elastomer coating on its external part

The hydrodynamic design of its sealing lip reduces radial load, preventing any backflow towards the engine and ensuring perfect separation between critical areas of the system.

Every detail of this seal has been designed to maximize its lifespan, enhance the overall reliability of the powertrain, and facilitate its integration into modern production lines.

Features of our high-performance seal for electric motors

Here are the benefits and features of Nova Seal:

| Speed | Up to 40 m/s |

| Service temperature | - 40°C to + 180°C |

| Sealing | Bidirectional sealing |

| Fluid compatibility | All synthetic ATF fluids commonly used in electric drivetrains and gearboxes. |

| Benefits |

|

Laboratory tests confirm the performance of this new generation of seal, designed to sustainably support the development of electric mobility.

Nova Seal, the seal that protects your components and maximizes their efficency

High-performance materials for extreme conditions

With our expertise in elastomer formulation, we have developed compounds capable of withstanding high temperatures, aggressive fluids and repeated mechanical stress:

- ACM / ACM-HT : for long-term thermal stability

- FKM : exceptional resistance to chemical fluids and heat

- Specials FKM : exceptional resistance to chemical fluids, heat and cold

- HNBR : exceptional mechanical and chemical resistance, even at low temperatures

- NBR : good mechanical properties and good wear resistance

PFAS-free blends

A seal developed with e-mobility stakeholders

At France Joint, we work with OEMs and tier 1 automative suppliers to create sealing solutions adapted to real-world conditions. That's why Nova Seal was created.

It reduces friction losses, improves energy efficiency and extends the range of electric vehicles.

Its innovative design ensures long life, minimal wear and reduced maintenance requirements. Manufactured from high-performance materials, it withstands extreme temperatures while limiting energy loss.

Compact and tolerant of misalignment, it integrates easily into modern architectures.

The Nova Seal is suitable for 100% electric vehicles (cars, commercial vehicles, buses, heavy goods vehicles), plug-in and non-plug-in hybrids, high-performance drive axles and compact propulsion systems for modular platforms.

Choosing and installing the right e-axle seal: what you need to know

Five technical criterias must be evaluated when you choose a seal:

- Temperature

- Rotation speed

- Possibles misalignments

- Fluid/material compatibility

- Integration and maintenance constraints

For the best set-up, you need to:

- Respect the recommended tolerances

- Check the surface conditions

- Apply lubrication suitable for assembly

Ready to improve the reliability of you electric axles with Nova Seal?

Less mechanical losses with our electric axle seal

By limiting lubricant leaks and reducing friction at rotating interfaces, Nova Seal directrly contributes to minimizing mechanical power losses. This loss control helps extend the lifespan of internal vehicle compnents (bearings, shafts, gears, etc).

A high-performance seal to reduce maintenance costs

Financially, benefits are immediate: a better seal leads to fewer maintenance. This means fewer parts to replace and fewer unplanned downtimes. In addition, there are significant environmental benefits: reduced energy consumption, fewer lost or degraded lubricants, and less waste.

Towards better autonomy for electric vehicles

Nova Seal reduces friction losses and unnecessary heating. This mechanical optimization improves the overall efficiency of the transmission and therefore further conserves the energy available in the battery. By reducing theses efficiency losses, Nova Seal directly contributes to increasing the range of electric vehicles, a key factor in comepting with internal combustion envines over long distances.

Try Nova Seal now!

Contact our team to find out how to integrate this solution into your future electric vehicles.

Discover the product technical sheet:

Only on request