BECA 007 Piston

Description

The BECA 007 Piston profile is a machined guide ring or wear ring with a 30° angle cut as standard, made from glass-filled POM. Other types of cuts can be made.

Advantages

Great compression resistance

Great wear resistance

Water absorption limited to 0.2%

Good stiffness

Technical data

| Temperature | -50°C / +115°C (+140°C peak) |

|---|---|

| Speed | 1 m/s |

| Max. compression resistance | 170 N/mm² |

| Radial loads in dynamic applications | 40 N/mm² at 25°C |

Applications

Lifting trucks

Construction equipment

Agricultural machinery

Standard cylinders

Materials

Polyoxymethylene - POM

Dimensions

Installation dimensions

Installation dimensions

| ISO 10766 | Bore diameter | Groove diameter | Groove width | Seal thickness | Gap |

|---|---|---|---|---|---|

| ØD1 H9 | Ød1 h8 | L1 0/+0.20 | E | Z +/-0.50 | |

| * | 10.0 - 50.0 | D1 - 3.10 | 4.00 | 1.55 | 1.00 |

| * | 16.0 - 140.0 | D1 - 5.00 | 5.60 | 2.50 | 1.25 |

| * | 60.0 - 220.0 | D1 - 5.00 | 9.70 | 2.50 | 1.25 |

| * | 130.0 - 500.0 | D1 - 5.00 | 15.00 | 2.50 | 1.25 |

| * | 280.0 - 500.0 | D1 - 5.00 | 25.00 | 2.50 | 1.25 |

| * | 280.0 - 500.0 | D1 - 8.00 | 25.00 | 4.00 | 2.00 |

Other dimensions are possible, not taking ISO 10766 into consideration. Please contact our experts.

Materials

Polyoxymethylene - POM

Polyoxymethylene (POM or polyacetal) belongs to the thermoplastics, which have a number of advantages - strong mechanical resistance, good creep strength, high resistance to shocks, particularly at low temperatures, good wear resistance, good sliding coefficient, excellent machinability and good dielectric properties. The low water absorption coefficient, unlike polyamide (PA), also gives this material an excellent dimensional stability.

| Chemical resistance |

Aliphatic hydrocarbons (propane, butane, petroleum, diesel fuel) |

|---|---|

| Compatibility issue | Acids |

| Temperature range | -50°C/+115°C |

Design guidelines

Guide sizing

The following formulas calculate the height "H" of the piston guide holder while taking account of the gap "Z" necessary at the ends of the ring after fitting. This gap "Z" offsets the thermal expansion under the effects of temperature, and prevents intermediate pressures and drag pressures in the system.

H = (F x f) / (ØD1 x Cr)

where:

H = Min. height of guide (mm)

F = Max. radial force (N)

f = Safety coefficient (we recommend 2)

ØD1 = Bore diameter (mm)

Cr = Permissible radial load in dynamic applications (N/mm²)

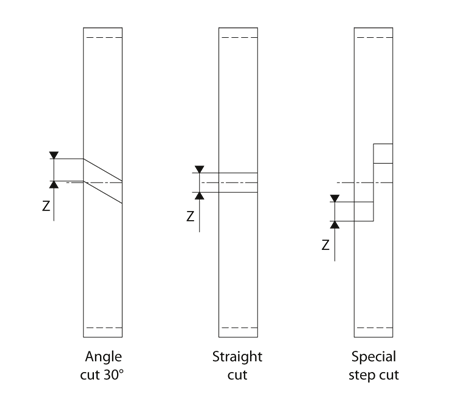

Types of cuts

The wear rings are made with a 30° angle cut as standard. Other types of cuts can be made on request, as shown in the diagram below.

Technical data

Extrusion gaps

| Bore diameter ØD1 |

Radial extrusion gap F/2 |

|

|---|---|---|

| 8.0 - 20.0 | 0.20 | 0.30 |

| 21.0 - 100.0 | 0.25 | 0.40 |

| 101.0 - 250.0 | 0.30 | 0.60 |

| 251.0 - 300.0 | 0.40 | 0.80 |

| 301.0 - 500.0 | 0.40 | 0.80 |

Surface roughness

| Roughness | Dynamic surface area | Static surface area | Groove flanks |

|---|---|---|---|

| Ra | 0.1 - 0.4 µm | ≤ 1.6 µm | ≤ 3.2 µm |

| Rz | 0.63 - 2.5 µm | ≤ 6.3 µm | ≤ 10.0 µm |

| Rmax | 1.0 - 4.0 µm | ≤ 10.0 µm | ≤ 16.0 µm |

Radius

| Bore diameter ØD1 |

Radius R1 |

|---|---|

| ≤ 250.0 | 0.20 |

| > 250.0 | 0.40 |

|

007.3253202

|

325,00 | 320,00 | 25,00 | 2,50 |

|

007.3303251

|

330,00 | 325,00 | 15,00 | 2,50 |

|

007.3303252

|

330,00 | 325,00 | 25,00 | 2,50 |

|

007.3353301

|

335,00 | 330,00 | 15,00 | 2,50 |

|

007.3353302

|

335,00 | 330,00 | 25,00 | 2,50 |

|

007.3403351

|

340,00 | 335,00 | 15,00 | 2,50 |

|

007.3403352

|

340,00 | 335,00 | 25,00 | 2,50 |

|

007.3453401

|

345,00 | 340,00 | 15,00 | 2,50 |

|

007.3453402

|

345,00 | 340,00 | 25,00 | 2,50 |

|

007.3503451

|

350,00 | 345,00 | 15,00 | 2,50 |

|

007.3503452

|

350,00 | 345,00 | 25,00 | 2,50 |

|

007.3603551

|

360,00 | 355,00 | 15,00 | 2,50 |

|

007.3603552

|

360,00 | 355,00 | 25,00 | 2,50 |

|

007.3703651

|

370,00 | 365,00 | 15,00 | 2,50 |

|

007.3703652

|

370,00 | 365,00 | 25,00 | 2,50 |

|

007.3803751

|

380,00 | 375,00 | 15,00 | 2,50 |

|

007.3803752

|

380,00 | 375,00 | 25,00 | 2,50 |

|

007.3903851

|

390,00 | 385,00 | 15,00 | 2,50 |

|

007.3903852

|

390,00 | 385,00 | 25,00 | 2,50 |

|

007.4003951

|

400,00 | 395,00 | 15,00 | 2,50 |

|

007.4003952

|

400,00 | 395,00 | 25,00 | 2,50 |

|

007.4504451

|

450,00 | 445,00 | 15,00 | 2,50 |

|

007.4504452

|

450,00 | 445,00 | 25,00 | 2,50 |

|

007.5004951

|

500,00 | 495,00 | 15,00 | 2,50 |

|

007.5004952

|

500,00 | 495,00 | 25,00 | 2,50 |